Most Common Wood Deck Materials

Pressure-Treated Wood

Pressure-treated wood is one of the most common wood decking materials on the market. This wood is the result of a process that uses extremely high pressure to inject a preservative into the wood, making it rot and insect resistant.

Another great benefit is its price: Pressure-treated wood is on the cheaper side of the pricing spectrum compared to redwood or cedar, and it is often more widely available due to its popularity.

The problem with this type of wood is that it can be unstable, especially when you choose the lowest price over quality. Lesser grade pressure-treated wood can sometimes shrink, warp or twist. If it’s possible with your budget, we recommend you pay a higher price for higher-grade lumber and opt for a pre-stained product.

Redwood

Just like the name suggests, redwood wood decking material is prized for its reddish-brown hues and tones that seem to sparkle in the sunlight. The aesthetic of this wood is highly sought after as the color creates a dramatic effect, offers a warm tonal range and gives flare without the aid of a saturated stain.

Naturally robust California Redwood is a sustainable wood when sourced ethically, and it’s resistant to warping. Redwood’s durable stability keeps your deck looking great for longer.

Potential downsides are that redwood needs to be maintained by applying a sealer, and it requires routine maintenance to reseal it every few years. The farther you are away from the California coast, the more money you’ll spend. Unfortunately, many redwood forests have been over-sourced, and only 1% of the old-growth redwood trees remain globally.

Cedar

Cedar wood is considered softwood and has been used as a reliable decking material for generations. Much like redwood, it has a natural resistance to rot and pests, making it a highly desirable deck option. Cedar also gives off a pleasing, calming smell with a recognizable scent, giving your home a comforting, familiar feeling.

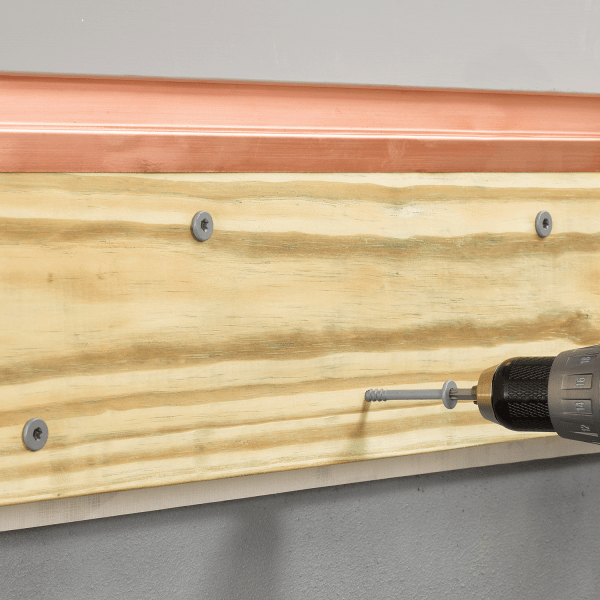

However, some builders find cedar to be too soft for decking and it has a higher intensity of splintering if you forgo a skilled professional as your installer. Hire a builder skilled in fastening cedar deck boards, utilize the best screws for cedar and build your deck with the best fasteners for cedar — then, you’re good to go. Similar to redwood, old-growth cedars are sometimes harvested too often, so try to find a reputable, ethically sourced supplier to purchase from if you can.

Mahogany

Mahogany wood gives your deck a beautiful and long-lasting look. It comes from hard, reddish-brown timber in tropical trees and is often used in high-quality furniture. With the right builder, it can absolutely be used for a deck build.

Because of its beauty and longevity, mahogany is an extremely pricey option. If you’re looking for a large deck job, your cost will be significantly higher than other materials. Due to this drastic price difference and growing demand, there are more and more suppliers who are logging and shipping mahogany to the United States illegally. So it’s important to ensure you know where your wood originates from.

Ipe

Ipe, also known as Brazilian walnut, comes from the forests of Central and South America. It is particularly durable due to its density. Buyers rave that it weathers fantastically and looks gorgeous. If you’re in an area prone to wildfires, Ipe has the same Class A fire rating as concrete or steel, making it a safer choice.

However, Ipe is rare, so it’s both hard to find and expensive. It’s also difficult to cut, due to its density. You have to pre-drill the holes in order to install it, which is time-consuming.

The Best Screw Type for Each Wood Deck Material