Source

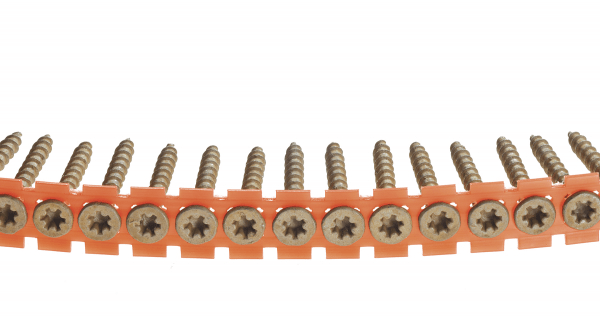

FastenMaster’s PAMFast Cement Board screws are a great option for cement board, as they are designed for attaching USG Durock® and Hardiebacker® tile to wood on any site. The thread design and modified wafer head on the PAMFast Cement Board screws deliver a consistent countersink and holding power.

The screws come with the PAMDrive Recess, eliminating bit grinding and cam-outs. Whatever your project needs are (plywood, heavy metal fixtures, etc.), the PAMFast Cement Board screws come in 1 ¼” and 1 ⅝” sizes.

Paired with FrameFAST, you can change the way you frame with one screw, one tool and three interchangeable heads that give you accurate installation angle, precise offset and optimized thread engagement every time. With FrameFast, you can install five times faster than traditional connectors and drive job site productivity.

If you want to use galvanized screws instead, we recommend the FastenMaster ThruLOK Through-Bolt Replacement. The ThruLOK system combines the strength of a through-bolted connection with the speed of a LOK fastener with no predrilling required. On top of cement board, it can also be used for multi-ply beam applications, decks posts, carrying beams and more.

ThruLOKs replace traditionally carriage and through-bolts in applications ranging from 4 ½” to 9 ½”. It has a three-part assembly that includes a screw, a patent-pending Paddle Point™, an engineered washer and a LOK nut. It installs with an 18-volt cordless drill with no drill bits or wrenches required. And because of its galvanized coating, it meets the IRC ACQ corrosion requirement and makes itself suitable for cement boards for a lifetime performance guarantee.

Interested in learning more about FastenMaster and how we can help you with your cement board project? Check out our wide range of cement board products.

Are you a contractor looking to grow in your career? Become a PROStar member, a program open for professional contractors. Join today and become a part of an exclusive community of market-leading professional contractors who value connection strength, innovation and code-compliance in building practices.