Choosing the right screws is crucial for construction projects. The durability and safety of any build, whether residential or commercial, depend on these small yet vital components. Structural screw shear strength plays a significant role in providing robustness and reliability in various applications.

With a wide range of options available, it’s important to understand their shear strength and versatility. This article provides builders and contractors with a comprehensive guide to making informed decisions for their construction needs.

Understanding Structural Screw Shear Strength and Its Measurement

Shear strength is a critical parameter that describes a screw’s ability to resist forces that cause it to slide or shear off at the point where it joins two materials. This measure is vital in ensuring the durability and safety of connections in construction projects.

How Shear Strength Is Measured

The shear strength of structural screws is determined through a testing process where a force is applied parallel to the screw’s axis. The key steps include:

Setup: The screw is placed in a testing machine designed to apply a parallel force.

Force Application: Force is gradually increased until the screw fails or shears. This force is applied at a controlled rate and the maximum load the screw can withstand before failure is recorded.

Measurement: The critical value noted is the maximum load capacity, measured in pounds-force (lbf). This figure represents the direct load the screw can support before it shears off.

Significance of Measurement in LBF

Measuring shear strength in LBF offers a straightforward understanding of a screw’s load capacity. This approach is practical, and it provides direct insights into the performance of fasteners under operational stresses. It simplifies the selection process for engineers and builders and ensures that the chosen screws can withstand the expected loads and contribute to the structural integrity of the construction.

This method emphasizes the direct load-bearing capacity of screws to aid in the design and construction of safer, more reliable structures by ensuring that all fasteners meet the required performance standards.

The Structural Screw Shear Strength of The LOK Fastener Series: Engineering Excellence for Every Joint

FastenMaster provides comprehensive structural shear strength information for its LOK screws to help builders and contractors make data-driven decisions.

Listed below is an explanation of each Fastenmaster structural screw that includes their applications, dimensions, and shear strength

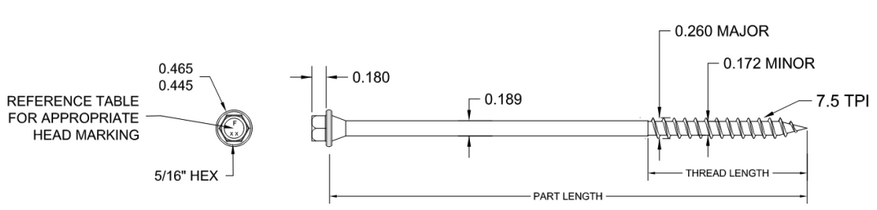

TimberLOK is the solution for securely attaching rafters, trusses, headers, and stair stringers that feature sharp points and aggressive threads for fast penetration into dense woods to streamline the installation process.

TimberLOK Dimensions

Unthreaded Shank Diameter: .189 (Inch)

Outside Thread Diameter: .260 (Inch)

Allowable Tensile: 1,300 (LBF)

Allowable Shear: 940 (LBF)

View the Technical Evaluation Report™ on the TimberLok Fastener.

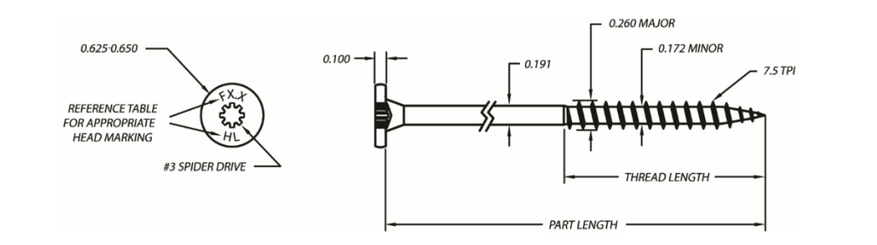

HeadLOK: Heavy-Duty Versatility

HeadLOK stands out for its versatility across applications, including deck framing and wood-to-wood connections by offering a higher design shear than traditional lag screws to boost connection strength.

HeadLOK Dimensions

Unthreaded Shank Diameter: .19 (Inch)

Outside Thread Diameter: .260 (Inch)

Allowable Tensile: 1,215 (LBF)

Allowable Shear: 965 (LBF)

View the Technical Evaluation Report™ on the HeadLOK Fastener.

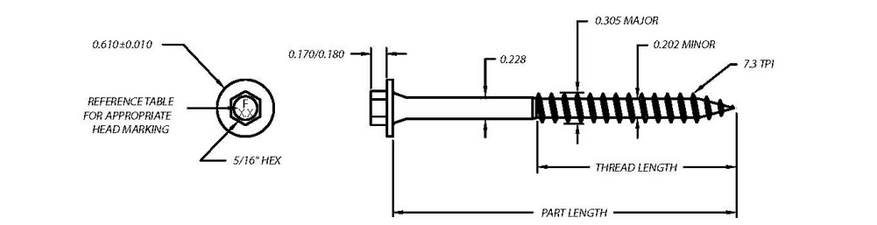

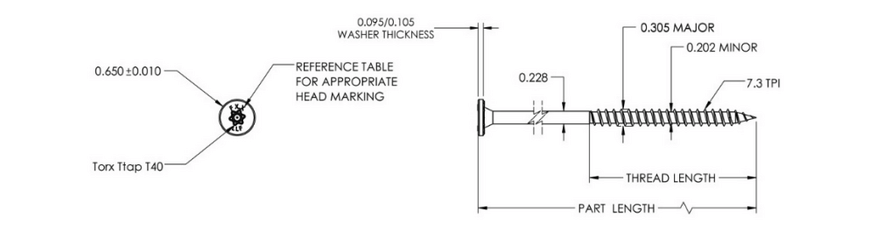

LedgerLOK: Ledger Board Security

Designed for attaching deck ledger boards with efficiency, LedgerLOK features a unique flat head and TORX® ttap® drive system for a seamless finish that blends aesthetics with robust fastening performance.

LedgerLOK Dimensions

Unthreaded Shank Diameter: .228 (Inch)

Outside Thread Diameter: .305 (Inch)

Allowable Tensile: 1,833 (LBF)

Allowable Shear: 1,235 (LBF)

View the Technical Evaluation Report™ on the LedgerLOK Fastener.

VersaLOK:

VersaLOK Dimensions

Unthreaded Shank Diameter: .228 (Inch)

Outside Thread Diameter: .305 (Inch)

Allowable Tensile: 1,833 (LBF)

Allowable Shear: 1,235 (LBF)

View the ICC-ES Evaluation Report on the VersaLOK Fastener.

ThruLOK: Through-Bolt Alternative

An efficient replacement for through-bolts, ThruLOK is ideal for multi-ply beams, deck posts, and carrying beams that combine holding power with ease of installation for scalable applications and is backed by comprehensive testing and code compliance.

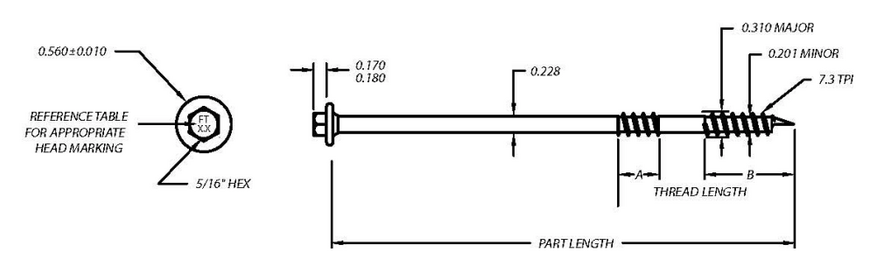

ThurLOK Dimensions

Unthreaded Shank Diameter: .228 (Inch)

Outside Thread Diameter: .310 (Inch)

Allowable Tensile: 1,970 (LBF)

Allowable Shear: 1,235 (LBF)

View the Technical Evaluation Report™ on the ThruLOK Fastener.

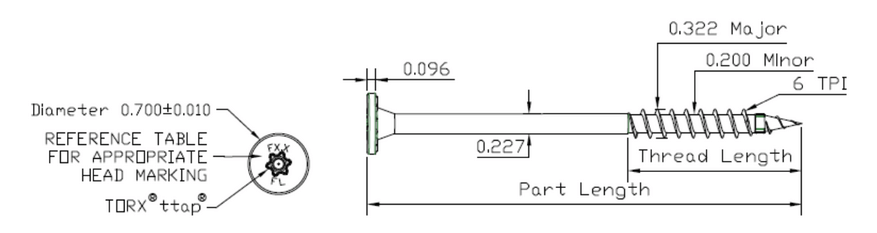

FlatLOK: Multi-Ply Mastery

Specifically designed for multi-ply dimensional and engineered wood connections, FlatLOK facilitates single-sided installations that are suitable for various elevations. It complies with the latest ICC standards to ensure safe use in ACQ or treated lumber.

FlatLOK Dimensions

Unthreaded Shank Diameter: .227 (Inch)

Outside Thread Diameter: .322 (Inch)

Allowable Tensile: 1,940 (LBF)

Allowable Shear: 1,230 (LBF)

View the Technical Evaluation Report™ on the FlatLOK Fastener.

Comparative Insights: LOK Line Versus Traditional Fasteners

When compared to traditional lag bolts, FastenMaster LOK screws stand out for their shear strength, ease of installation, and versatility. The LOK line demonstrates a commitment to innovation by offering solutions that not only meet but exceed the demands of modern construction practices.

Installation Guidelines and Best Practices

For optimal results, it’s important to follow FastenMaster’s recommended installation guidelines and best practices. Using the right tools and techniques ensures that each screw performs to its full potential in order to contribute to the overall strength and durability of the construction.

Secure Your Build with Precision and Strength: FastenMaster LOK Solutions

Every detail matters in construction, especially the shear strength of structural screws, which underscores the necessity for safety in projects.

The LOK line of structural screws by FastenMaster stands out for its exceptional shear strength, user-friendly design, and dependability to provide enduring stability for your projects.

Reach out to us today for more details!